LED (Light Emitting Diodes) lights!!

Well, so you are an enthusiast, a DIY person or perhaps curious to know about the LED lights. You have heard about them and seen them. They are almost everywhere, in shopping centres, at your friends’ place and many other places.

Let’s discuss briefly about what these are, the different types that are available, how much voltage/current they need and last but not the least-can you have your own set up of LED lights-opposed to the ready-made all in one pack’s that are available for sale?

(Trust me whilst the ready-made packs are the simplest of all and you can be up and running in no time, there is a LOT more that you can do by Designing Your Own (DYO) set-up).

Light Emitting Diodes (LEDs) come in various types and operate at different voltage levels depending on their design and intended application. Here are some common types of LEDs and their typical voltage requirements:

- Standard LEDs: These are the most common type of LEDs and typically operate at a voltage of around 1.8 to 2.2 volts. The actual voltage may vary slightly depending on the colour of the LED. Red LEDs tend to have a lower forward voltage, around 1.8 volts, while blue and white LEDs have a higher forward voltage, closer to 3.3 volts.

- High-Power LEDs: High-power LEDs are designed to emit a lot of light and can operate at higher voltages. They usually require voltages in the range of 3 to 3.7 volts. These LEDs are commonly used in applications where brightness is crucial, such as automotive headlights and high-intensity lighting.

- RGB LEDs: RGB (Red, Green, Blue) LEDs consist of three separate LED chips in one package, allowing for a wide range of colours by adjusting the intensity of each colour. Each of the three chips typically operates at a voltage of around 2 to 2.2 volts.

- SMD LEDs: Surface Mount Device (SMD) LEDs are designed for compact and surface-mount applications. They come in various sizes and colours, and the voltage can range from about 2 to 3.3 volts, depending on the specific model.

- Bi-colour LEDs: These LEDs can emit two different colours, typically red and green. They have two anodes and a common cathode (or vice versa). Each colour usually operates at around 1.8 to 2.2 volts.

- IR (Infrared) LEDs: Infrared LEDs, used in applications like remote controls and IR communication, typically operate at around 1.2 to 1.5 volts.

- UV (Ultraviolet) LEDs: UV LEDs, used for applications like curing and counterfeit detection, typically require voltages in the range of 3 to 4 volts.

- Alphanumeric and Dot Matrix LEDs: These types of LEDs are often used in displays and signage. They come in various sizes and operate at different voltage levels depending on the specific model.

- Specialty LEDs: There are specialty LEDs designed for niche applications, such as high-intensity UV-C LEDs for disinfection, which may have unique voltage requirements.

What’s the Voltage (V) and Current (I) required to run a led?

Calculating the voltage and current requirements for LED strips involves considering the specifications of the LED strip and how you plan to power and connect them. Here’s how to calculate the voltage and current for LED strips:

Determine the LED Strip Specifications:

You need to know the specifications of the LED strip, which typically include:

1. Operating Voltage (Vf):- This is the voltage required for each segment of LEDs on the strip. It’s usually specified per segment or meter of the strip.

2. LED Forward Current (If):

- This is the current required for each segment of LEDs on the strip. It’s also specified per segment or meter of the strip.

3. Number of LEDs per Segment:

- LED strips are often divided into segments, and the specifications are given per segment. For example, a common LED strip might have 60 LEDs per meter, which means each segment has 60 LEDs.

Calculate the Total Voltage:

Multiply the operating voltage (Vf) by the number of segments or meters you plan to connect in series. This will give you the total voltage required for the LED strips in your setup.

Total Voltage (V_total) = Vf * Number of Segments or MetersCalculate the Total Current:

Multiply the LED forward current (If) by the number of segments or meters you plan to connect in parallel. If you connect segments in parallel, the current requirements add up.

Total Current (I_total) = If * Number of Segments or MetersPower Supply Selection:

Select a power supply or driver that can provide the calculated total voltage (V_total) and current (I_total). It’s essential to choose a power supply that can deliver the required voltage and, at the same time, provide a current equal to or greater than the total current.

Consider Safety Margin:

It’s a good practice to add a safety margin when selecting the power supply. This ensures that the power supply can handle fluctuations and provides some extra capacity. A safety margin of 10-20% is typically sufficient.

For example, let’s say you have a 5-meter LED strip with the following specifications:1.Vf per meter: 12 volts2.If per meter: 0.6 amperes (600 milliamperes)

Calculations:

Total Voltage (V_total) = 12 V/meter * 5 meters = 60 V

Total Current (I_total) = 0.6 A/meter * 5 meters = 3 A

In this case, you would need a power supply that can provide 60 volts and at least 3 amperes of current, with a safety margin applied, if desired.

BUT hey, how about the power rating of the LED Driver/Transformer? i.e. how many watts??

Good thinking. Let’s look into this.

To calculate the power in watts (W) of an LED driver, you’ll need to know the output voltage and the output current provided by the driver. The formula to calculate power is straightforward:

Power (W) = Voltage (V) × Current (A)

In the case of an LED driver, this formula translates to:

Power (W) = Output Voltage (V) × Output Current (A)

Here’s how to use this formula to calculate the power in watts of an LED driver:

1. Determine the Output Voltage: Check the specifications of your LED driver to find the specified output voltage. This is typically denoted as Vout or V, and it represents the voltage supplied to the connected LED or LED array.

2. Determine the Output Current: Similarly, check the specifications for the specified output current. This is typically denoted as Iout or I, and it represents the current supplied to the LEDs. It is often measured in amperes (A) or milliamperes (mA).

3. Calculate the Power: Once you have the output voltage and output current values, simply multiply them to find the power in watts.

Power (W) = Output Voltage (V) × Output Current (A)

For example, if your LED driver has an output voltage of 12 volts (V) and an output current of 0.5 amperes (A), the power supplied by the driver would be:

Power (W) = 12 V × 0.5 A = 6 W

So, the LED driver provides 6 watts of power to the connected LEDs.

This calculation is essential for selecting the right LED driver for your LED lighting application and ensuring that it can adequately power your LED setup without overloading or underpowering it. Always use the specifications provided by the manufacturer and consider any safety margins or efficiency losses when designing your LED lighting system.

Additionally, check the manufacturer’s specifications for the specific LED strip you’re using, as these values can vary between different products.

Is there any such thing as additional power injection for LED light strips?

Yep, that’s true. LED’s when joined together or are of longer lengths would need additional power feed. Why? Coz there is a phenomenon called Voltage Drop that comes into play. Let’s look at this Voltage Drop thingie!

Voltage drop in LED strips is the reduction in voltage along the length of the strip due to the resistance of the conductors and components in the strip. Voltage drop can cause dimming or uneven brightness in long LED strip installations. To calculate voltage drop in an LED strip, you can use the following formula:

Voltage Drop (Vd) = Current (I) x Length (L) x Resistance (R)

- Voltage Drop (Vd): This is the amount by which the voltage decreases along the length of the strip.

- Current (I): This is the current in amperes (A) that the LED strip consumes per unit length. You can find the current rating in the LED strip’s specifications. If it’s given in milliamperes (mA), convert it to amperes by dividing by 1000.

- Length (L): This is the length of the LED strip in feet or meters. You’ll need to use consistent units for all variables.

- Resistance (R): This is the resistance of the conductors in the LED strip. You can usually find this in the LED strip’s specifications as “Ohms per unit length” or “Ohms per meter.” If it’s not provided, you can measure it directly by using a multimeter.

Here’s an example of how to put the above into action:

- Determine the LED strip’s current rating per unit length (usually given in A/m or A/ft) from the manufacturer’s specifications.

- Measure the length of the LED strip you plan to use in feet or meters.

- Find the resistance of the LED strip conductors in ohms per unit length from the manufacturer’s specifications or measure it with a multimeter if necessary.

- Plug these values into the formula to calculate the voltage drop:

Voltage Drop (Vd) = Current (I) x Length (L) x Resistance (R)

The result will be the voltage drop along the LED strip in volts.

Too much theory?? Need an example, OK I heard you, see below:

For example, if you have an LED strip that consumes 0.2 A/m, the length of the strip is 5 meters (L = 5), and the resistance is 0.2 ohms/m, you can calculate the voltage drop as follows:

Vd = 0.2 A/m x 5 m x 0.2 ohms/m = 0.2 V

In this example, the voltage drop along the 5-meter LED strip would be 0.2 volts, which is a relatively small amount and should not cause significant brightness loss. If the voltage drop is too high for your application, you may need to inject power at various points along the strip.

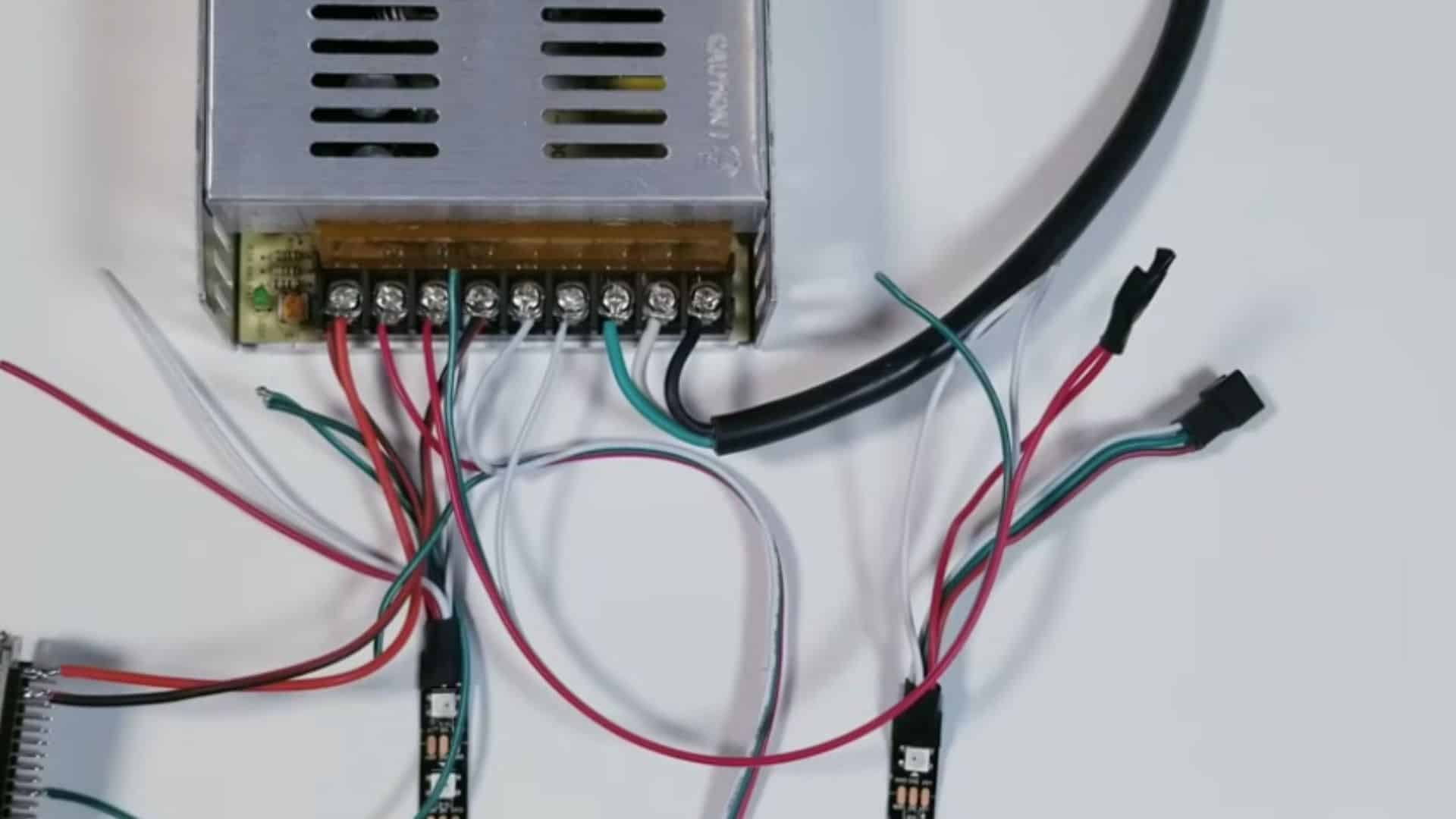

Power injection – How to do it?

To inject power into an LED strip, follow these general steps:

1. Determine the Required Injection Points:

- Divide your long LED strip into smaller sections (usually 3-6 feet or 1-2 meters in length) to reduce voltage drop.

- Calculate the voltage drop for each section based on the LED strip’s specifications and the distance from the power source.

2. Choose Power Injection Points:

- Place power injection points strategically along the strip’s length, typically at both ends of each section.

- Make sure each injection point is located near the power source, and use connectors designed for your LED strip type (e.g., solderless connectors or connectors compatible with your strip’s shape and size).

3. Prepare the Injection Points:

- Cut the LED strip at the selected points.

- Strip the insulation from the ends of the cut LED strip wires.

- Connect the LED strip wires to the power injection connectors.

4. Supply Sufficient Power:

- Use a separate power supply for each injection point to provide ample power.

- Ensure the power supply voltage matches the LED strip’s voltage requirements, and use a power supply with the correct amperage rating.

5. Secure Connections:

- Use soldering, solderless connectors, or other secure methods to connect the power supply wires to the LED strip wires.

- Make sure the connections are solid and well-insulated to prevent short circuits.

6. Test the Setup:

- Before mounting the LED strips in their final location, test each section to ensure they are functioning correctly and consistently in terms of brightness and colour.

7. Mount the LED Strips:

- Secure the LED strips in their final locations, keeping in mind that they may require additional securing points due to the power injection.

8. Provide Adequate Ventilation:

- Ensure that the LED strips and any connected wires have sufficient ventilation to prevent overheating, especially if you’re injecting power at multiple points.

9. Monitor and Adjust:

- Regularly check the LED strips for proper operation, and be prepared to make adjustments if you notice any issues with brightness or colour consistency.

By following these steps, you can effectively inject power into long LED light strips, ensuring that the entire length receives the necessary power for consistent and reliable illumination.

This is all theory? So is there any practical video or something that can help a person actually see how this is done?

Umm yep this is theory, BUT hey, there are people out there who have done wonderful work in this area. Let me not reinvent the wheel and instead point you there. One of my favourites is the video by Chris Maher. Go check it out!!.

Ready to power up? Browse our range of LED Lights and accessories — everything you need to start your custom lighting project.

Disclaimer: To Read our Disclaimer, Please Click here